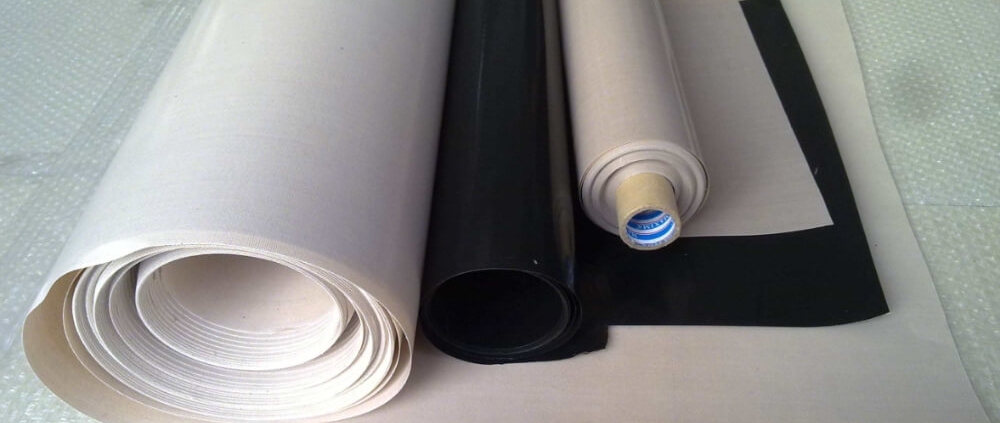

PTFE coated fiberglass cloth is a is made of high performance glass fiber fabric impregnated with PTFE emulsion. It is a high-performance, multi-purpose composite material new product. Due to the special high temperature resistance and anti-stick properties of PTFE coated fiberglass cloth, it is also a typical application in solar laminators. This application includes two applications, the use of the inner layer of the laminator and the use of the conveyor belt in the laminator. Therefore, PTFE coated fiberglass cloth is also called solar laminated cloth.

PTFE coated fiberglass cloth used in laminator inner layer

When the solar back sheet is laminated, it is PTFE coated fiberglass cloth + glass + EVA + cell + EVA + back plate + PTFE coated fiberglass cloth, mainly using the high temperature resistance and anti-stickiness of PTFE to prevent EVA from sticking to the laminating machine .

Specification

Large laminators generally use 1.8 meters, 2.2 meters, and 2.4 meters wide PTFE coated fiberglass cloth, and the length is generally within 3.6 meters, small laminators generally use 1.25 meters wide cloth.

Conveyor belt for laminator

The battery board in the laminator should be conveyed by a high temperature resistant and anti-sticking PTFE conveyor belt. Since the laminator is evacuated, in order to prevent the cloth from being adsorbed on the back board, the surface of the PTFE coated fiberglass cloth is required to be textured and rough relatively.

Specification

1.8 meters, 2.2 meters, 2.4 meters wide, the length is generally about 10 meters

Jiujiang PTFE

Jiujiang PTFE tefloncoatedfiberglass

tefloncoatedfiberglass